Pressurized Reaction Chamber

The Pressurized Reaction Chamber (PRC) is used primarily to create Substrate (to create HDPE Pellets), HDPE Pellets (to create HDPE Sheets), and Ethylene (an efficient source of fuel used in the Gas-Burning Generator). It has a variable speed and energy usage dependent on the materials/gasses it is creating.

Contents

Usage

The Pressurized Reaction Chamber accepts a liquid, a gas, and a material(s); it uses these three substances to create another material(s) and some leftover gas. Like many other Mekanism machines, it has configurable sides; by default, it accepts gas from the left, accepts liquid from the back, and outputs gas on the right.

Recipes

| Energy/tick | Total Energy | Speed | Input Liquid | Input Gas | Input Material | Output Material | Output Gas |

|---|---|---|---|---|---|---|---|

| 5 J/t | 500 J | Normal (5s) | Water (10 mB) | Hydrogen (10) | Bio Fuel (2) | Substrate (1) | Ethylene (100) |

| 205 J/t | 82 KJ | Slow (20s) | Water (200 mB) | Ethylene (100) | Substrate (1) | Substrate (8) | Oxygen (10) |

| 1000 J/t | 70 kJ | Normal (3.5s) | Liquid Ethylene (50 mB) | Oxygen (10) | Substrate (1) | HDPE Pellet (1) | Oxygen (5) |

Setup

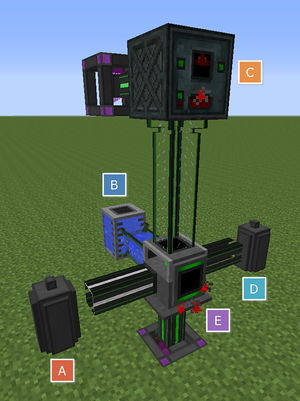

The image on the left is an example setup of a Pressurized Reaction Chamber creating Substrate from Water, Hydrogen, and Bio Fuel.

A - A Gas Tank outputting Hydrogen. Gas Tanks output through their side with a red rectangular mark into Pressurized Tube. You can obtain Hydrogen naturally by using an Electrolytic Separator.

B - A Portable Tank outputs water through Mechanical Pipe. Notice that the end of the Mechanical Pipe touching the Portable Tank has been configured using a Configurator to "PULL". You can obtain water naturally by using the Electric Pump.

C - A powered Crusher crushes natural ingredients into Bio Fuel and outputs it through Logistical Transporter piping. Again, note that the piping has been set to "PULL".

D - The resulting Ethylene (Gas) from the reaction is sent through Pressurized Tube into a Gas Tank.

E - The Pressurized Reaction Chamber itself. It has been configured to accept items from its top (Items - Red), accept Energy through its bottom (Energy - Green), accept gases from its left (Gases - Red), accept fluids from its back (Fluids - Yellow), and output gases from its right (Gases - Blue - Auto Eject: On).

Crafting Recipe

Tips

- If you need to clear a liquid or gas from the input gauges, use the Gauge Dropper; simply open the Pressurized Reaction Chamber's GUI (by right-clicking it), take an empty Gauge Dropper from your inventory, and click on the gauge with the liquid or gas that you want to extract. You can then either shift+right-click on the ground with the Gauge Dropper to empty it and continue to extract the gas or liquid by repeating the previous steps, or drop it into a Gas Tank or Portable Tank's input slot on its interface (marked with either an "I" or a "-") to move the substance into the receptacle without wasting it.

- Remember that Liquid Ethylene is not the same as Ethylene. To create HDPE Pellets, you must first convert the Ethylene into Liquid Ethylene using a Rotary Condensentrator. Have it accept Ethylene from its "G" (Gas) side, and output Liquid Ethylene from its "L" (Liquid) side, and leave it in "Condensentrating" mode.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||