Fission Reactor

This page is a work in progress! Many essential things are missing.

The Fission Reactor is a multiblock structure that allows for variable input rates of Fissile Fuel. The reactor uses either Sodium or water as a coolant. Power is generated by converting the generated heat into power in an Industrial Turbine. With water cooled reactors, this is done by directly piping steam into an Industrial Turbine. Sodium cooled reactors use a Thermoelectric Boiler as a heat-exchanger to cool down the Superheated sodium and heat up water into Steam.

Contents

Construction

- The structure must be a cuboid of minimum size 3x4x3 (along X, Y and Z), up to 18x18x18.

- The edges of the outer shell must be made of Fission Reactor Casing

- The faces of the outer shell can be either Fission Reactor Casing, Reactor Glass, Fission Reactor Port or Fission Reactor Logic Adapter

- The interior of the cube can be either air or fission control rods"

- A control rod is which are a 1x1 block wide column made of 1 to 15 Fission Fuel Assembly and a single Control Assembly at the top

- Control rods must not touch each other. The highest control rod density can be achieved by placing them in a checker board patters.

Some example control rod setups as seen from the top ( is for Fission Reactor Casing or Reactor Glass, R is for a control rod):

CCCCC CCCCC

CCC C C CR RC

CRC CR RC C R C

CCC C C CR RC

CCCCC CCCCC

A fission reactor requires at least 4 Fission Reactor Ports:

- One coolant input

- One coolant output

- One Fissile Fuel input

- One waste output

Output ports must be configured to the proper output type by crouching and right-clicking them with a Configurator.

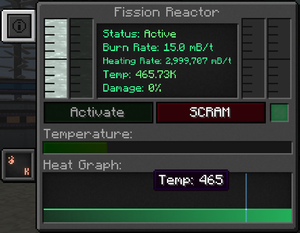

Reactor GUI

The reactor's GUI shows it's status, burn rate, heating rate, temperature and structural damage (health).

Status

The reactor's running status, either active or disabled.

To activate the reactor, either click the green activation button, or send a redstone signal to a Fission Reactor Logic Adapter configured in activation mode (just right click the Fission Reactor Logic Adapter block to configure it).

The reactor stops when a player clicks the red SCRAM button or if a redstone signal on a logic adapter goes from 1 to 0.

Burn Rate

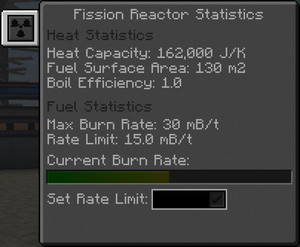

The burn rate is the rate at which the reactor will burn Fissile Fuel. For a newly formed reactor, it is automatically set to 0.1 mB/t. It can be changed in the reactor's statistics tab.

The theoretical maximum burn rate is 1 mB/t per [[Fission Fuel Assembly in the reactor, but the effective maximum burn rate depends on a number of factors (see #Safe operation).

Heating Rate

The heating rate represents how much coolant is heated up per tick. The actual value depends on the burn rate. For a burn rate of one 1 mB/t, the heating rate is:

- 20000 mB/t for a water cooled reactor

- 200000 mB/t for a sodium cooled reactor

For safe operation, the external cooling setup must be able to handle that much heated coolant per tick. See the relevant section.

Temperature

The core's temperature: green OK, yellow: danger zone, red: imminent meltdown.

TODO: add actual figures.

Damage

This indicates the actual structural damage of the reactor. When a reactor reaches critical temperature, it will start taking damage and this value will go up. The damage value of a reactor that has overheated but been stopped on time to prevent a meltdown will slowly go down on its own, no player intervention is needed.

TODO: need more tech details: how fast is damage recovery? does it recover if running in the danger zone (yellow heat value), etc.

Cooling and power production

Cooling a fission rector and converting the generated heat into power can be done in two ways: water cooling and sodium based cooling.

"Things to know" about how pipes/tubes work in Mekanism (to be moved into its own page):

- The pump rate is the rate at which the pipe can pump gases/fluids from a container when set in pull mode

- The capacity is how much the single pipe adds to to the pipe network's capacity (a pipe network being all pipes connected together)

- At each tick, a pipe network tries to dump its whole buffer (i.e. up to the networks' capacity) evenly among all connected receivers

- In effect, with no pipes set to pull mode, the actual transfer rate is limited by the minimum value of the providers ejection rate into the network and the network's capacity

- If the ejection rate of a provider is lower than the pipe's rate, setting the pipe to pull mode will override the provider's ejection rate

Water based cooling

Water based cooling is sufficient for small setups, i.e. reactors with less than 20 Fission Fuel Assembly and a max burn rate of 20 mB/t. Beyond that, it gets hard to keep the temperature of the reactor core within acceptable parameters.

Setup

- pipe water into a Fission Rector Port configured as input only

- Connect a Fission Reactor Port configured as coolant output to the steam input valve of an Industrial Turbine.

- Connect a Mechanical Pipe from one of the Industrial Turbine's vents back to the coolant input of the reactor (or back to the same same mechanical pipe network from the first step).

Important: the Industrial Turbine must have Saturating Condensers in order to be able to condense steam into water and pipe that water back to the reactor. The max water output from a turbine can be seen in its statistics tab. The actual value is 64000 mB of water per condenser. Condensers must be placed at the same level as the Electromagnetic Coils or above them (a single coil is sufficient for 4 blades, so this leaves plenty of room at the same level).

A water cooled reactor has a heat rate of 20000 mB of water for 1 mB of Fissile Fuel burnt.

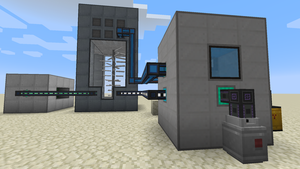

Sample build

The picture to the right shows a minimal fission reactor setup. From left to right: Induction Matrix, Industrial Turbine, Fission Reactor. The reactor has a single Fission Fuel Assembly. It takes Fissile Fuel from its front input port, Nuclear Waste is output to the right to a Nuclear Waste Barrel. In the back behind the reactor, there are two Electric Pumps feeding the coolant loop with fresh water if need be. The Industrial Turbine is a minimal 5x9x5. This setup generates 71.4 kJ/t when burning Fissile Fuel at its maximum of 1 mB/t. That's roughly 2.5 times less power than a Gas-Burning Generator burning Ethylene.

Sodium based cooling

For larger reactors, with a burn rate higher than 20 mB/t, Sodium is a much more efficient coolant and allows very high burn rates at lower core temperatures. Sodium based cooling requires a Thermoelectric Boiler as an intermediate heat-exchanger to cool down the Superheated sodium from the reactor and heat up water into Steam.

The Thermoelectric Boiler has been updated in Makanism v10 to make it use heated coolant as a heat source. The Boiler Valves can be configured with a Configurator (crouch + right click) to make them input only, output steam or output coolant.

Setup

Setup a Thermoelectric Boiler + Industrial Turbine as described on the boiler page with the exception that in step 7, you will need two Boiler valves on a steam catch or steam cavity layer, one for steam output, the other for coolant output.

It is important to build the boiler with water cavity layers (step 3c of the boiler's setup) in order to have a decent enough water + heated coolant storage capacity.

Next, connect the the boiler steam output (at or above the steam catch layer) to the turbine steam input, and pipe water back from one of the turbine's vents to one of the boiler's inputs at the heater or water cavity layers.

Setup fully some fully upgraded Electric Pumps (1 KJ/t for 1000 mB of water per tick) to inject fresh water in the water-steam loop. It is necessary to keep them running in order to keep the boiler's water tank full when running at high heat rates (compared to what the boiler can support). How many pumps are required is left to the reader to experiment with (see #Safe Operation).

Finally, connect the reactor's heated coolant output to one of the boiler's inputs at the heater or water cavity layers, and the boiler's coolant output to one of the reactor's inputs. While the boiler's valves must be placed in the proper layers. the placement of the reactor's ports does not matter.

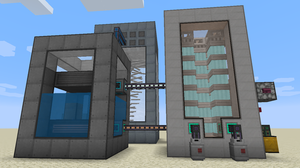

Sample build

The picture to the right shows a 5x9x5 sodium cooled fission reactor, backed by a fairly small 5x7x5 Thermoelectric Boiler and a 7x13x7 turbine with 18 blades. It produces 3.85 MJ/t (1.54 MFE/t, 385.63 kEU/t) at peak burn rate (30 mB/t). Note that this same turbine could work with a reactor twice that size, but the boiler would need to be extended. On the right side of the reactor there is a crude, yet effective breaker-switch system (see #Safe Operation).

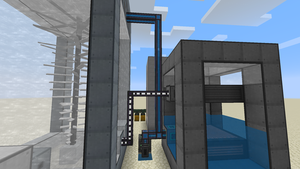

The second picture shows the boiler and turbine piping as well as a single pump (which is not enough for this configuration).

Safe operation

TBD

Breaker switch

TBD

Radiation and nuclear waste handling

As a byproduct of burning Fissile Fuel, fission reactors produce Nuclear Waste which can be converted in either Polonium Pellet or Plutonium Pellet. Both conversion paths produce Spent Nuclear Waste as a byproduct (at a ratio of 10:1), which must be stored in Radioactive Waste Barrels. Nuclear Waste or Spent Nuclear Waste can be piped into a Nuclear Waste Barrel from its top side with a Pressurized Tube.

- Nuclear Waste is radioactive.

- All products and intermediate products of converting Uranium Ore to Fissile Fuel are not radioactive, i.e. safe to handle.

- Intermediate products and byproducts of recycling Nuclear Waste are radioactive: Polonium, Plutonium and Spent Nuclear Waste.

- Plutonium Pellets and Polonium Pellets are not radioactive.

Radiation can leak into the environment for the following reasons:

- Fission reactor overheating leading to a core meltdown (actually blowing up).

- Fission reactor running with its waste tank full.

- Breaking any block containing radioactive materials. Most notably Pressurized Tubes and Radioactive Waste Barrels, but also any machine (like a Pressurized Reaction Chamber containing radioactive materials. These can still be broken safely if they are somehow drained of their radioactive contents beforehand.

Nuclear Waste Barrels

TODO: move this to its own page

Waste Barrels are used to store (or as buffer for) Nuclear Waste and Spent Nuclear Waste. They delete their contents at a rate of 1 mB per minute.

The player can check the storage status of Nuclear Waste Barrels by crouching and right-clicking it with an empty hand. Green radiation particles start to appear as a barrel fills up (these are just a rough visual indicator of a barrel's fill ratio, not actual radiations).

Waste barrels cannot be moved by any means (pistons, cardboard box, etc.). Also because barrels containing any radioactive waste cannot be broken safely, the only way to safely move a non empty barrel it transfer its contents to another barrel before breaking it. This can be done by connecting a Pressurized Tube to its bottom side in pull mode.

Even if Waste Barrels are blast resistant, but pressurized tubes carrying waste to them are not. As a rule of thumb, do not allow creepers wandering around a fission reactor or waste transformation or disposal units.

Tips

- For any given reactor burn rate, the more turbine blades, the more energy is produced per mB of Fissile Fuel. As a result, the bigger the turbine the better. Also it is best to max out the rotor height and make trade-offs on the vents/condensers count. With a slightly shorter rotor, one could add more condensers and achieve higher burn rates and total power produced, but at a higher cost in terms of power produced per mB of Fissile Fuel burnt.