Fissile Fuel: Difference between revisions

No edit summary |

(add details, resize diagram) |

||

| Line 18: | Line 18: | ||

# Process the [[Uranium Hexafluoride]] in an [[Isotopic Centrifuge]] to get Fissile Fuel. | # Process the [[Uranium Hexafluoride]] in an [[Isotopic Centrifuge]] to get Fissile Fuel. | ||

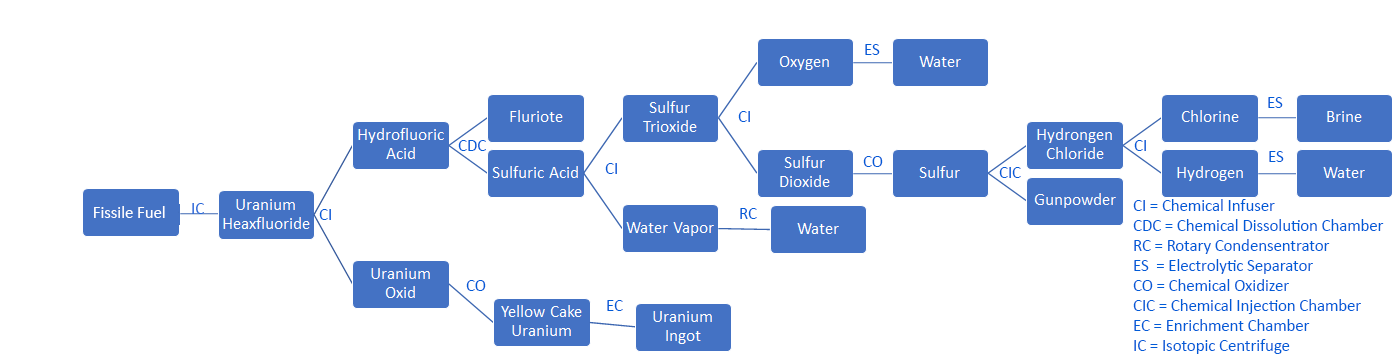

[[file:Production_fissile_fuel.png | [[file:Production_fissile_fuel.png|Fissile Fuel Processing Diagram]] | ||

== Detailed Production Chain == | |||

To produce Fissile Fuel, from the basic inputs of: Water, Coal (or similar), [[Oxygen]], [[Fluorite]] and [[Uranium Ingot]]s is a involved process. | |||

Ideally you would have 3 [[Chemical Infusers]], and 2 [[Chemical Oxidizers]]. | |||

As well as one each of: [[Enrichment Chamber]], [[Pressurized Reaction Chamber]], [[Rotary Condensentrator]], [[Chemical Dissolution Chamber]], [[Isotropic Centrifuge]]. | |||

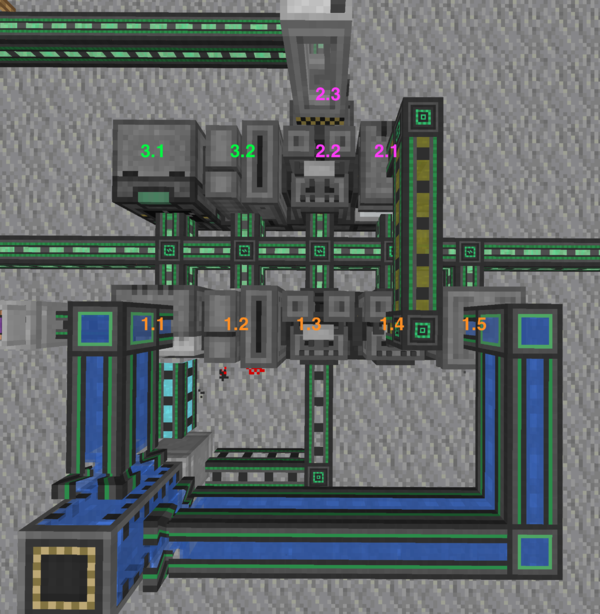

Listed here are the steps in counter clockwise order from the screenshot below. | |||

The first step, of creating [[Sulfur Dust]] has multiple paths. | |||

Using Coal is convenient, but alternatives include [[Hydrogen Chloride]] + Gunpowder (From crushing Flint) | |||

# Making Sulfuric Acid: (Orange below) | |||

## [[Pressurized Reaction Chamber]]: [[Oxygen]] + Water + Coal (etc) = [[Sulfur Dust ]] | |||

## [[Chemical Oxidizer]]: [[Sulfur Dust]] = [[Sulfur Dioxide]] | |||

## [[Chemical Infuser]]: [[Sulfur Dioxide]] + [[Oxygen]] = [[Sulfur Trioxide]] | |||

## [[Chemical Infuser]]: [[Sulfur Trioxide]] + [[Water Vapor]] (A) = [[Sulfuric Acid]] (B) | |||

## [[Rotary Condensentrator]]: Water = [[Water Vapor]] | |||

# Making Fissile Fuel: (Pink below) | |||

## [[Chemical Dissolution Chamber]]: [[Sulfuric Acid]] + [[Fluorite]] = [[Hydrofluoric Acid]] | |||

## [[Chemical Infuser]]: [[Hydrofluoric Acid]] + [[Uranium Oxide]] = [[Uranium Hexafluoride]] | |||

## [[Isotopic Centrifuge]]: [[Uranium Hexafluoride]] = '''Fissile Fuel''' | |||

# Making Uranium Oxide (Green below) | |||

## [[Enrichment Chamber]]: [[Uranium Ingot]] = [[Yellow Cake Uranium]] | |||

## [[Chemical Oxidizer]]: [[Yellow Cake Uranium]] = [[Uranium Oxide]] | |||

[[File:Fissilefuel.png|600px|Detail of one way to layout machines to make fissile fuel]] | |||

Revision as of 23:20, 27 March 2021

This article is a stub.

Please help us by expanding it

Please help us by expanding it

Fissile Fuel is "burned" in a Fission Reactor to produce Nuclear Waste and heated coolant.

Fissile Fuel Production Chain

- Refine Uranium Ore into Uranium Ingots, preferably by the Tier 4 ore quintupling process.

- Process the Uranium Ingots in an Enrichment Chamber to produce Yellow Cake Uranium.

- Process the Yellow Cake Uranium in a Chemical Oxidizer to produce Uranium Oxide.

- Process Fluorite with Sulfuric Acid (such as from the Tier 4 ore process) in a Chemical Dissolution Chamber to produce Hydrofluoric Acid.

- Combine the Hydrofluoric Acid and Uranium Oxide in a Chemical Infuser to produce Uranium Hexafluoride.

- Process the Uranium Hexafluoride in an Isotopic Centrifuge to get Fissile Fuel.

Detailed Production Chain

To produce Fissile Fuel, from the basic inputs of: Water, Coal (or similar), Oxygen, Fluorite and Uranium Ingots is a involved process. Ideally you would have 3 Chemical Infusers, and 2 Chemical Oxidizers. As well as one each of: Enrichment Chamber, Pressurized Reaction Chamber, Rotary Condensentrator, Chemical Dissolution Chamber, Isotropic Centrifuge.

Listed here are the steps in counter clockwise order from the screenshot below.

The first step, of creating Sulfur Dust has multiple paths. Using Coal is convenient, but alternatives include Hydrogen Chloride + Gunpowder (From crushing Flint)

- Making Sulfuric Acid: (Orange below)

- Pressurized Reaction Chamber: Oxygen + Water + Coal (etc) = Sulfur Dust

- Chemical Oxidizer: Sulfur Dust = Sulfur Dioxide

- Chemical Infuser: Sulfur Dioxide + Oxygen = Sulfur Trioxide

- Chemical Infuser: Sulfur Trioxide + Water Vapor (A) = Sulfuric Acid (B)

- Rotary Condensentrator: Water = Water Vapor

- Making Fissile Fuel: (Pink below)

- Making Uranium Oxide (Green below)

Cookies help us deliver our services. By using our services, you agree to our use of cookies.